Power supply issues are one of the most common hidden problems faced by industries. Many factories and commercial facilities invest heavily in advanced machines, automation systems, and electronic equipment, but often overlook the importance of stable voltage. Over time, voltage fluctuations can silently damage machines, increase downtime, and raise maintenance costs.

This is why choosing the right servo voltage stabilizer manufacturer in India is a critical decision for industrial buyers. This blog explains everything you need to know—what servo voltage stabilizers are, why they are important, how they work, where they are used, and how to select the right manufacturer—using simple and clear language that anyone can understand.

Why Power Stability Is So Important for Industries

Industrial equipment is designed to operate within a specific voltage range. When voltage goes above or below that range, machines may still run, but internal components start to suffer damage. Motors may overheat, electronic boards may weaken, and sensors may give incorrect readings.

In many cases, industries experience frequent machine failures without realizing that unstable voltage is the root cause. Production delays, rejected products, and rising maintenance expenses are often the result of poor power quality.

A servo voltage stabilizer acts as a protective shield between the power supply and your equipment. It ensures that machines always receive safe and stable voltage, regardless of fluctuations in the incoming power.

Understanding Power Conditions in India

In many industrial areas, power supply conditions are not consistent. Voltage variations can occur due to:

- Grid load changes

- Peak power demand

- Long-distance power distribution

- Weather conditions

- Aging electrical infrastructure

These challenges make voltage regulation essential, especially for industries running sensitive or high-value equipment. Servo voltage stabilizers are specifically designed to handle such conditions and deliver consistent output voltage.

What Is a Servo Voltage Stabilizer?

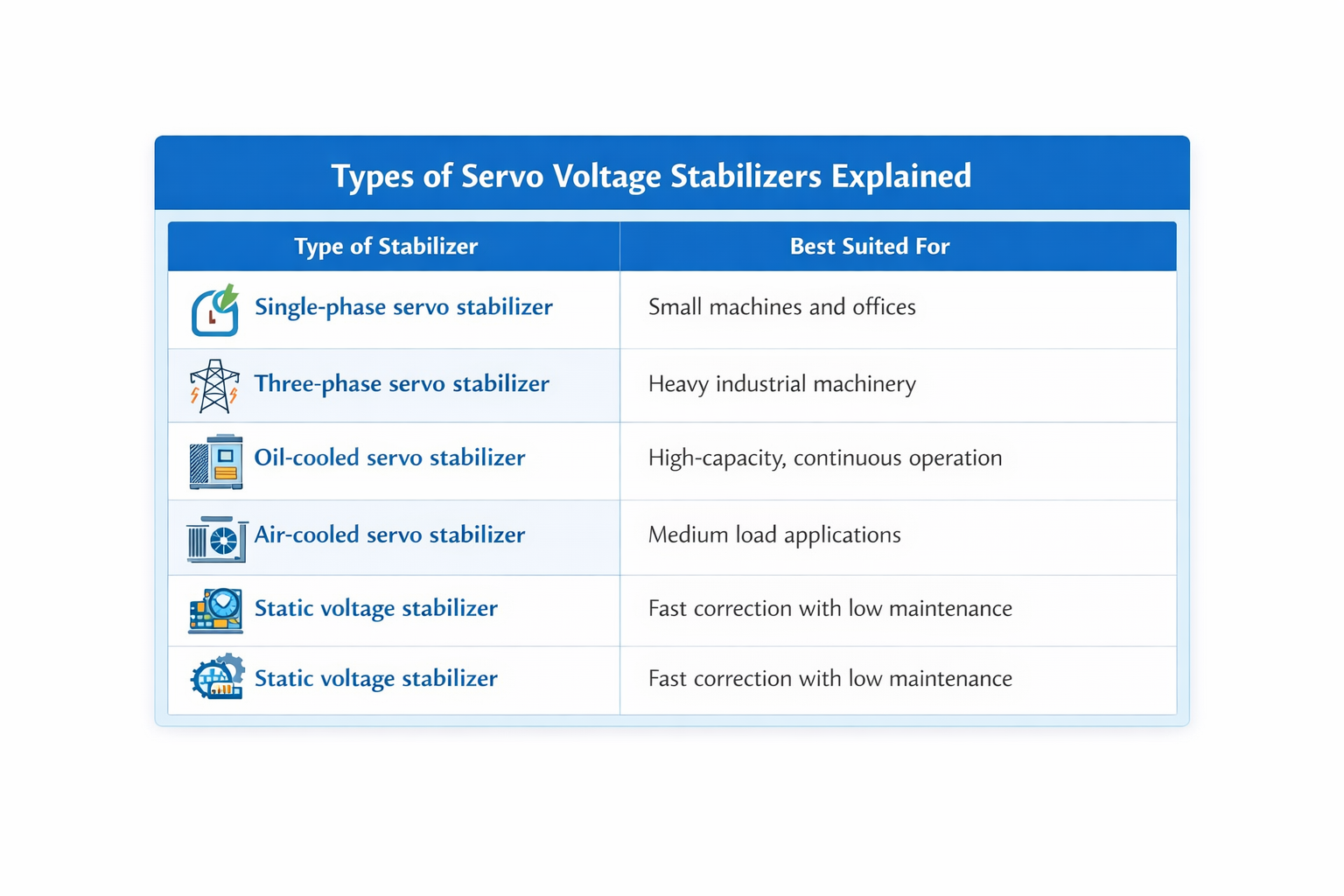

A servo voltage stabilizer is an automatic electrical device that controls voltage using a servo motor mechanism. It continuously monitors the incoming power supply. If it detects that the voltage is too high or too low, it automatically corrects it and supplies safe voltage to the connected equipment.

Unlike basic stabilizers, servo stabilizers offer high accuracy and fast response. Once installed, they operate automatically and require minimal human intervention.

How a Servo Voltage Stabilizer Works

The working process of a servo voltage stabilizer is simple but highly effective. It constantly monitors voltage levels and makes real-time adjustments.

- The stabilizer senses the incoming voltage

- It compares the voltage with the preset safe range

- If correction is needed, the control circuit activates

- The servo motor adjusts the transformer winding

- Stable voltage is supplied to the equipment

This entire process happens within seconds, ensuring uninterrupted operation and equipment protection.

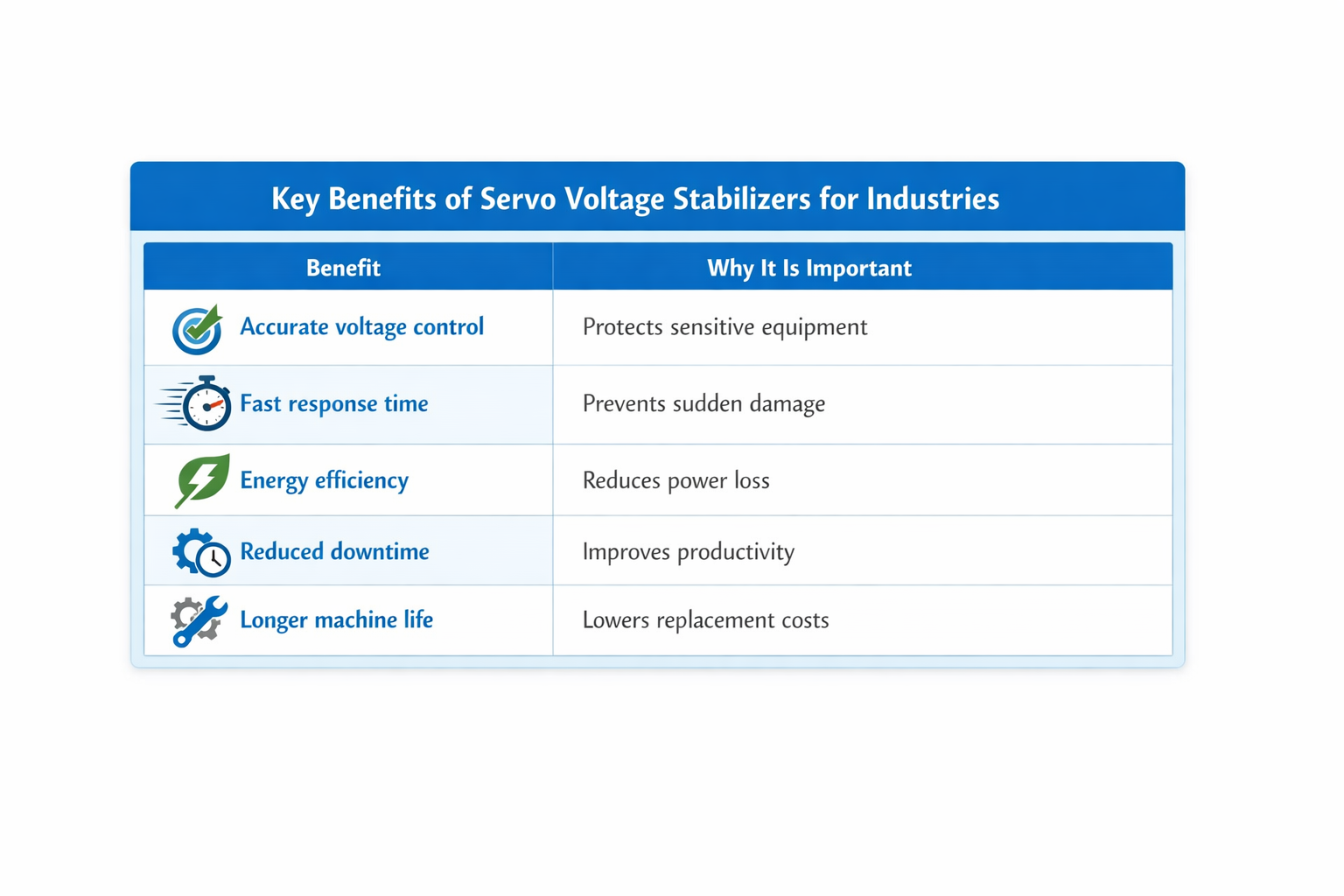

Why Industries Prefer Servo Voltage Stabilizers

Industries prefer servo stabilizers because they are designed for continuous operation, high load handling, and precise voltage regulation. Unlike conventional stabilizers, servo stabilizers can handle wide voltage fluctuations without affecting machine performance.

They help industries maintain consistent output quality, reduce unexpected breakdowns, and improve overall efficiency.

Industries That Commonly Use Servo Stabilizers

Servo voltage stabilizers are widely used across multiple industries due to their reliability and performance.

Manufacturing units use them to protect CNC machines, robotic arms, and automation systems. Healthcare facilities rely on them to ensure safe operation of MRI machines, X-ray equipment, and laboratory devices. Data centers depend on stable voltage to prevent server damage and data loss.

Other industries that benefit from servo stabilizers include textile mills, printing presses, hotels, commercial complexes, shopping malls, and renewable energy plants such as solar installations.

Why Manufacturer Quality Makes a Big Difference

Two stabilizers with the same rating can perform very differently depending on how they are built. The quality of the transformer, copper winding, control circuit, and protection features all affect performance and lifespan.

A reliable manufacturer focuses on durability, accuracy, and safety. Poor-quality stabilizers may be cheaper initially, but they often fail sooner and lead to higher long-term costs.

How to Choose the Right Servo Voltage Stabilizer Manufacturer in India

When selecting a manufacturer, buyers should look beyond price and consider long-term reliability.

A good manufacturer offers:

- High-quality transformers with copper windings

- Custom solutions based on voltage range and load

- Compliance with safety and quality standards

- Reliable after-sales service and warranty

- Experience in industrial power solutions

Choosing an experienced manufacturer ensures consistent performance and peace of mind.

Benefits of Choosing an Indian Manufacturer

Indian servo voltage stabilizer manufacturers understand local power conditions better than international suppliers. Their products are designed specifically for the voltage challenges commonly faced by industries.

They also offer faster delivery, easier communication, local service support, and cost-effective pricing. This makes Indian manufacturers a practical and reliable choice for industrial buyers.

Installation and Maintenance Considerations

Proper installation is essential for optimal stabilizer performance. Load calculation should be accurate, wiring should be of good quality, and grounding must be properly done. Adequate ventilation is also necessary, especially for high-capacity stabilizers.

Regular maintenance, including inspection and cleaning, helps prevent unexpected failures and extends the life of the stabilizer.

Cost and Long-Term Value

The cost of a servo voltage stabilizer depends on capacity, voltage range, cooling type, and customization. While high-quality stabilizers may have a higher initial cost, they offer better long-term value.

They help reduce machine repair expenses, minimize downtime, improve energy efficiency, and extend equipment life. For most industries, the return on investment becomes clear within a short period.

Future Trends in Servo Voltage Stabilizer Technology

Servo stabilizer technology continues to evolve. Modern systems now include features such as remote monitoring, intelligent fault alerts, and energy-efficient designs. Manufacturers are also focusing on compact designs and environmentally friendly cooling methods.

These advancements help industries manage power more effectively and improve operational reliability.

Conclusion

A servo voltage stabilizer is not just an electrical component—it is a critical protection system for industrial operations. Choosing the right servo voltage stabilizer manufacturer in India ensures stable power, reduced equipment damage, and smooth production.

For industries that value reliability, safety, and long-term efficiency, investing in a high-quality servo voltage stabilizer is a smart and necessary step.

FAQs

- What is the primary function of a servo voltage stabilizer?

To regulate voltage fluctuations and maintain a stable output supply. - How does a servo stabilizer differ from a relay stabilizer?

Servo stabilizers offer faster, more precise, and continuous voltage regulation. - What industries need servo stabilizers the most?

Manufacturing, healthcare, IT, printing, textiles, and heavy engineering. - How do I choose the correct kVA rating?

Calculate total load requirement with safety margin. - Are servo stabilizers energy-efficient?

Yes, they reduce power loss and improve equipment efficiency. - What maintenance does a servo stabilizer require?

Periodic inspection, cleaning, calibration, and electrical testing. - How long does a servo stabilizer last?

Typically 10–15 years with proper maintenance. - Can servo stabilizers handle sudden voltage spikes?

Yes, they provide surge and spike protection. - Are custom industrial stabilizers available?

Yes, manufacturers offer tailored solutions.

10. Is after-sales service important?

Yes, it ensures reliable long-term performance.