Electrical systems are the backbone of any modern business, powering machinery, equipment, and processes that keep everything running smoothly. However, with power instability, voltage fluctuations, and safety risks constantly looming, protecting your electrical system has become more critical than ever. That’s where an isolation transformer comes in as an unsung hero in safeguarding and enhancing the performance of electrical equipment.

Let’s dive into how an isolation transformer works and why it is essential for ensuring safety, efficiency, and a long lifespan for your electrical infrastructure.

What is an Isolation Transformer?

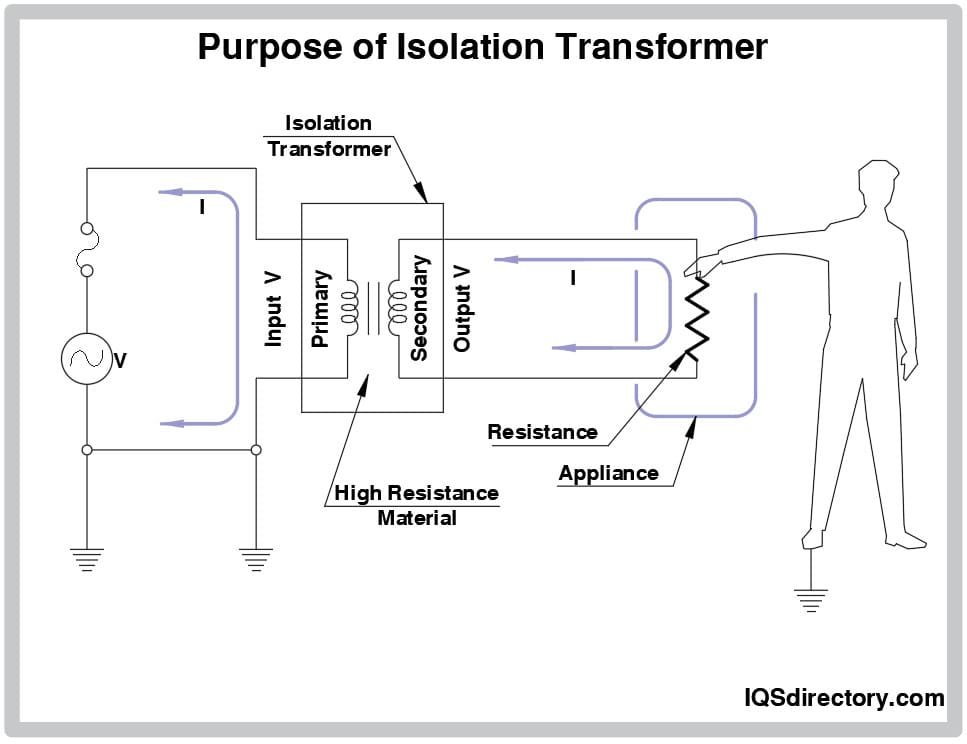

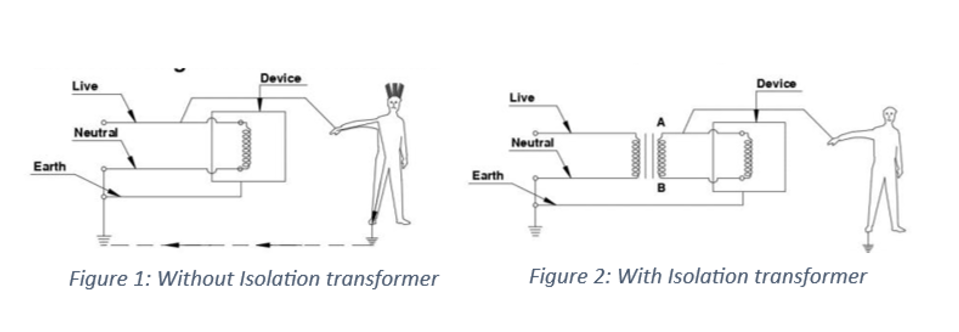

An isolation transformer is a type of transformer that separates the electrical circuits from the input power supply to the output power system. This separation helps to prevent electrical faults from transferring between the two systems, ensuring the safety of the connected equipment. It is typically used to isolate sensitive devices from disturbances in the power line, offering clean and stable electricity.

For industries in India, such as manufacturing or IT services, protection from unstable power sources is a growing concern. This is why servo voltage stabilizers in India are often used to handle power surges and fluctuations. However, even with these stabilizers in place, isolation transformers provide an additional layer of security, particularly for sensitive equipment that could be damaged by high-frequency noise or power spikes.

The Core Benefits of Using an Isolation Transformer

The importance of isolation transformers can’t be overstated. Here are some key advantages that make them a must-have in many industries:

1. Enhanced Safety

An isolation transformer primarily protects against electrical shock and fire hazards. By isolating the output from the electrical supply, it prevents short circuits, grounding problems, and other electrical faults from spreading. This is especially critical in industries like healthcare, where equipment such as MRI machines or ECG monitors must remain unaffected by sudden voltage spikes.

2. Noise Reduction

Power lines often carry high-frequency electrical noise from various sources, including motors, compressors, and other heavy machinery. Isolation transformers filter out this noise, ensuring that your sensitive equipment receives clean, stable power. This is especially crucial for laboratory equipment or precision machinery that requires minimal interference to function optimally.

3. Improved Efficiency and Longevity

An isolation transformer helps in maintaining a consistent voltage level, reducing wear and tear on equipment. By ensuring that the power is stable, your equipment operates at its best efficiency. This leads to reduced operational costs, fewer maintenance issues, and an extended lifespan for your devices.

4. Power Surge Protection

While surge protectors are often used, an isolation transformer provides an additional layer of defense against sudden power surges. For instance, during thunderstorms or from issues in the local grid, the transformer will isolate your equipment from these potentially damaging voltage spikes.

Oil-Cooled vs. Air-Cooled Isolation Transformers

When choosing an isolation transformer, businesses often face the decision between oil-cooled and air-cooled systems. Both types serve the same primary purpose but differ in design and application.

Oil-Cooled Transformers

Oil-cooled isolation transformers use mineral oil or synthetic oils to dissipate heat. These are particularly effective for heavy-duty industrial applications that require high-power capacities. The oil helps maintain the temperature of the transformer, preventing it from overheating. For instance, transformers used in power plants or large manufacturing units often require oil-cooled systems because of their higher power ratings (up to several KVA).

Oil-cooled transformers can handle power ranges from 10 KVA to 1000 KVA and are preferred in environments where transformers need to manage high load conditions over extended periods.

Air-Cooled Transformers

Air-cooled transformers, on the other hand, rely on natural or forced air circulation to regulate the temperature. They are usually more compact and are suitable for smaller installations where space and cooling efficiency are key considerations. With power ratings generally ranging from 1 KVA to 50 KVA, air-cooled transformers are often used in commercial establishments, data centers, and IT operations.

Choosing between oil-cooled and air-cooled transformers depends on the specific needs of your business. For example, if your facility operates high-power machinery that demands constant power supply, an oil-cooled stabilizer will be the ideal choice.

Isolation Transformer to reduce risk

Isolation Transformers in Real-World Applications

Let’s take a look at how isolation transformers are being used in various industries.

Healthcare Sector

In hospitals, isolation transformers are crucial for protecting life-saving equipment such as ventilators, defibrillators, and imaging systems. These devices require a stable and clean power supply to function correctly. Without proper isolation, fluctuations and electrical noise could affect their performance and lead to costly downtime or malfunction. By using isolation transformers, hospitals ensure continuous operation and patient safety.

Industrial Manufacturing

In manufacturing plants, sensitive machinery such as CNC machines, robotics, and precision tools require clean power to avoid malfunctions. Power fluctuations or electrical noise can lead to defects in the products, costing time and money. With isolation transformers, manufacturers can ensure that their machines run smoothly without disruption, enhancing productivity and quality.

IT and Data Centers

For data centers, which are the backbone of modern communication, power consistency is critical. Any interruption in power could lead to data loss, system crashes, or equipment damage. Isolation transformers provide the necessary protection to servers, routers, and other equipment, making them indispensable for businesses that rely on data integrity.

Understanding the Role of a Servo Stabilizer Manufacturer

As industries grow more dependent on complex electrical systems, companies often look for ways to secure their equipment from power-related issues. This is where a servo stabilizer manufacturer comes into play. These manufacturers design and build stabilizers that regulate voltage levels, ensuring your system receives the required power supply without sudden changes that could potentially harm your equipment.

When combined with an isolation transformer, a servo stabilizer offers comprehensive protection for electrical systems, safeguarding them from both voltage fluctuations and power surges. For instance, servo voltage stabilizers are popular in places like factories, IT facilities, and hospitals, where consistent and clean power is critical.

Conclusion: Power Protection for the Future

In conclusion, isolation transformers play a critical role in protecting and enhancing the safety and efficiency of electrical systems. By isolating equipment from power line disturbances, they ensure that sensitive devices operate smoothly, reducing the risk of damage and downtime. Whether in healthcare, manufacturing, or data centers, the importance of having a reliable isolation transformer cannot be overstated.

Moreover, pairing an isolation transformer with a lift stabilizer can further improve power quality, especially in high-rise buildings and areas where power outages are frequent. Lift stabilizers help ensure that your elevator systems receive stable power, preventing interruptions and ensuring smooth operation.

By investing in the right combination of power protection equipment like isolation transformers and stabilizers, businesses can boost their operational efficiency, protect their valuable assets, and ensure they are ready for the challenges of the future.