Introduction

In industries where precision, efficiency, and operational continuity are paramount, voltage fluctuations pose a significant challenge. Electrical equipment in factories, manufacturing units, and processing plants is highly sensitive to voltage variations, leading to performance issues, equipment failures, and even financial losses. A servo voltage stabilizer is a critical solution for maintaining consistent voltage levels, ensuring smooth industrial operations.

A reliable servo stabilizer manufacturer in Bangalore provides advanced voltage regulation solutions tailored to industrial requirements. These stabilizers protect machinery from voltage fluctuations, reducing downtime and increasing productivity. The implementation of servo stabilizers in industrial applications enhances energy efficiency, improves safety, and extends the lifespan of critical equipment.

This article explores the role of servo stabilizers in industrial applications, their working principles, advantages, and considerations before purchasing one for your facility.

1. Understanding Servo Voltage Stabilizers

A servo voltage stabilizer is an advanced voltage correction device that regulates voltage supply to industrial machinery. Unlike traditional stabilizers, which operate with step-based corrections, a servo stabilizer continuously monitors and adjusts the voltage output through a servo motor-driven transformer.

Working Principle of Servo Stabilizers

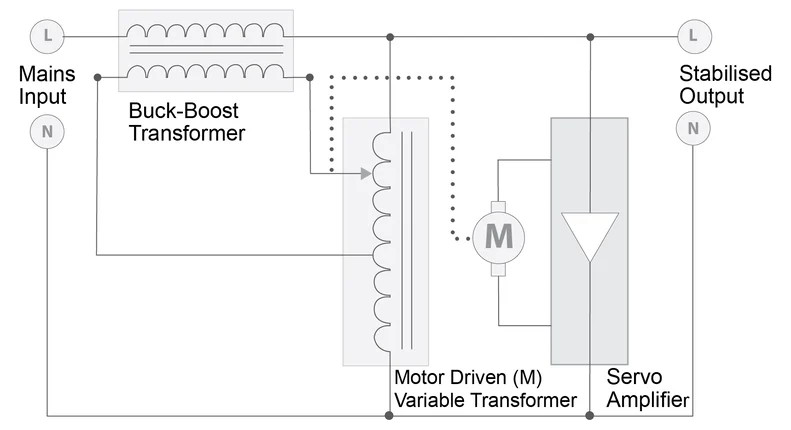

A servo stabilizer consists of the following key components:

- Servo Motor: Adjusts the position of the autotransformer for voltage correction.

- Buck-Boost Transformer: Regulates the voltage by either increasing or decreasing the input voltage.

- Control Circuit: Monitors the voltage and provides real-time adjustments.

- Carbon Brush Mechanism: Ensures smooth contact with the transformer windings for precision control.

When an industrial power supply experiences voltage fluctuations, the stabilizer’s control circuit detects the deviation. The servo motor adjusts the transformer’s winding position to correct the voltage, ensuring a stable output within the desired range.

2. Why Industries Need Servo Stabilizers

Industrial facilities operate large machines, automated systems, and electronic devices that demand a stable power supply. Voltage fluctuations can lead to:

- Machine Malfunctions: Erratic voltage can disrupt PLCs (Programmable Logic Controllers), causing operational failures.

- Energy Waste: Unstable voltage increases energy consumption and reduces efficiency.

- Equipment Damage: Electrical components like motors, pumps, and drives can fail due to overvoltage or undervoltage.

- Production Downtime: Interruptions in operations result in financial losses.

Servo stabilizers help industries by maintaining voltage consistency, ensuring uninterrupted processes, and optimizing overall power efficiency.

3. Applications of Servo Voltage Stabilizers in India

A servo voltage stabilizer in India is used across multiple industrial sectors where stable power is essential. Some key industries benefiting from servo stabilizers include:

1. Manufacturing & Automation

- Ensures smooth operation of CNC machines, injection molding equipment, and assembly lines.

- Prevents overheating and damage to industrial motors.

2. Textile Industry

- Maintains voltage stability for looms, sewing machines, and dyeing processes.

- Reduces rejection rates and improves fabric quality.

3. Pharmaceutical Industry

- Protects lab equipment, packaging machines, and HVAC systems from voltage variations.

- Ensures precise temperature and environmental control for drug production.

4. Healthcare & Medical Equipment

- Safeguards MRI scanners, CT scanners, and diagnostic tools from power fluctuations.

- Reduces risks of inaccuracies in medical tests due to unstable voltage.

5. Food Processing Industry

- Prevents power instability in refrigeration systems, conveyor belts, and food packaging machines.

- Ensures continuous production in bakeries, dairy units, and beverage plants.

6. Printing & Packaging

- Maintains accuracy in high-speed printing presses and digital printing machines.

- Prevents color variations caused by voltage inconsistency.

7. Data Centers & IT Infrastructure

- Protects servers, data storage units, and network devices from power surges.

- Reduces risks of data loss and system failures.

A servo voltage stabilizer in India is crucial for maintaining seamless operations in these industries, ensuring energy efficiency and long-term equipment reliability.

4. Key Advantages of Servo Stabilizers in Industrial Applications

Investing in a high-quality servo stabilizer brings multiple benefits to industries:

1. Precision Voltage Regulation

Servo stabilizers offer precise voltage correction, typically within ±1% of the desired voltage, making them more effective than traditional stabilizers.

2. Energy Efficiency

By preventing power wastage due to voltage variations, servo stabilizers improve overall energy efficiency and reduce electricity bills.

3. Increased Equipment Lifespan

By supplying stable voltage, servo stabilizers prevent wear and tear in electrical equipment, reducing maintenance costs.

4. Uninterrupted Operations

With stable power output, industrial machinery operates without unexpected shutdowns, improving production efficiency.

5. Surge and Short-Circuit Protection

Many modern servo stabilizers come with inbuilt surge protection, safeguarding equipment from power spikes and short circuits.

6. Remote Monitoring & Automation

Advanced stabilizers are integrated with IoT-based monitoring systems, allowing real-time tracking of voltage performance.

7. Reduced Carbon Footprint

Optimized voltage regulation leads to lower power wastage, making industries more energy-efficient and environmentally friendly.

5. Factors to Consider When Choosing a Servo Stabilizer

Before selecting a servo stabilizer, industries should evaluate several key parameters:

1. Voltage Range

Assess the input voltage fluctuations in your area and choose a stabilizer that can handle variations effectively.

2. Load Capacity

Servo stabilizers are available in different KVA ratings. Calculate the total power consumption of your industrial equipment to select the appropriate stabilizer.

3. Phase Type

- Single-phase stabilizers: Suitable for small-scale applications.

- Three-phase stabilizers: Required for large industries with heavy machinery.

4. Efficiency Rating

Choose a stabilizer with high efficiency (above 95%) to ensure minimal energy loss.

5. Response Time

A fast correction speed (typically 20–50 ms) ensures quick response to voltage fluctuations.

6. Protection Features

Look for features such as overload protection, short-circuit prevention, and surge suppression for enhanced safety.

7. Manufacturer’s Reputation

A trusted servo stabilizer manufacturer ensures better quality, warranty coverage, and technical support.

6. Installation & Maintenance Guidelines

Proper installation and maintenance enhance the longevity and performance of a servo stabilizer:

Installation Tips:

- Place the stabilizer in a well-ventilated area to prevent overheating.

- Ensure proper grounding to avoid electrical faults.

- Use correct cable sizing to match the stabilizer’s capacity.

Maintenance Practices:

- Regular Inspection: Check wiring connections and ensure smooth motor operation.

- Cleaning: Remove dust accumulation to maintain airflow.

- Oil-Level Monitoring (For Oil-Cooled Models): Prevent overheating issues.

- Load Testing: Periodically test the stabilizer under full load conditions.

Proper maintenance reduces downtime and enhances operational efficiency.

Conclusion: Choosing the Right Servo Stabilizer Manufacturer

A servo stabilizer is a vital investment for industries requiring uninterrupted power stability. Choosing a high-quality stabilizer from a reliable servo stabilizer manufacturer ensures enhanced efficiency, equipment protection, and cost savings in the long run.

When selecting a manufacturer, consider factors such as industry experience, product certifications, warranty policies, and customer support services. The right stabilizer will improve energy efficiency, reduce maintenance costs, and protect industrial equipment from voltage inconsistencies.

By implementing servo stabilizers, industries can optimize production processes, minimize downtime, and achieve higher operational efficiency—making them an indispensable component of modern industrial infrastructure.